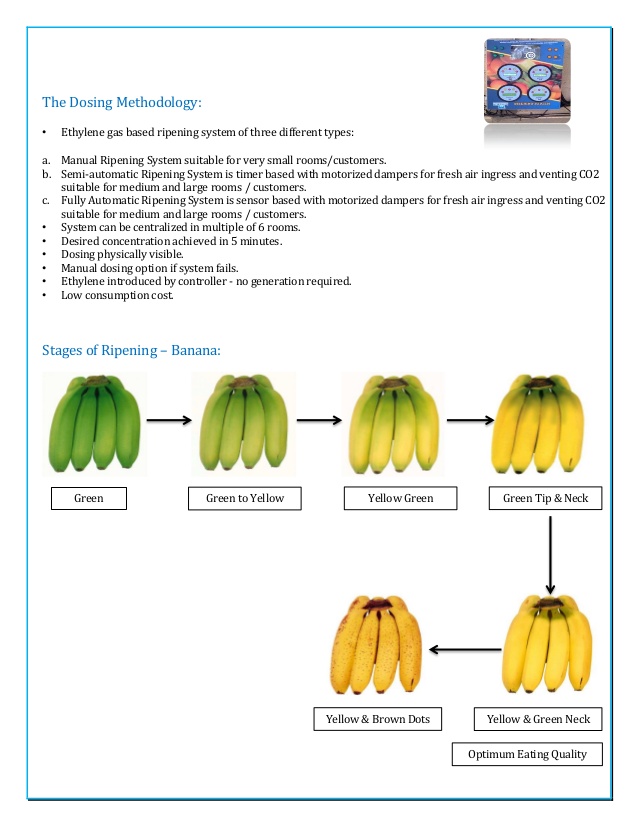

Ripening Chambers

GTA provides wide range of ripening chambers to maintain precise conditions which is required for specific applications. Our chambers considers factors such as temperature, humidity, specific gas emission levels and ventilation in each chamber are tuned to the levels depending on the client requirements.

Ethylene sensors with Manual Setup

Ripening is being processed using Ethylene gas cylinder or cans in cold rooms. GTA also offers gas analysers which can be taken inside the chamber to check the concentration of ethylene when gas is dosed inside the cylinder/can, while dosing analyser value of ethylene is measured and gas consumption is monitored accordingly. Ethylene measuring machine is reliable and durable and gas cylinder comes with a gas releasing apparatus which helps users to monitor the amount of gas required for ripening.

Features

- Portable -This automated system can be shifted from one chamber to another easily.

- Simple and fast

- Safe – There will not be any explosions if all the given instructions are followed strictly.

Automated Ripening Chambers

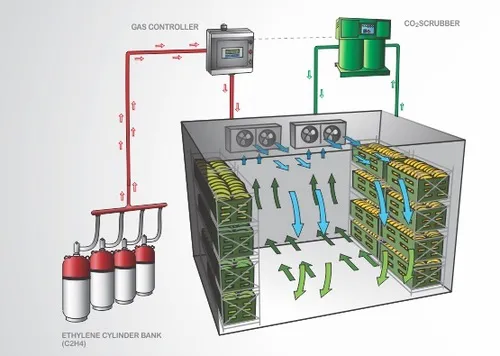

These kinds of rooms are fully automated ripening chambers which are also called as centralized Ripening System. This System Consists of an

- Gas Cylinder bank

- Centralized ripening controllers with analyser

This system controls the entire ripening cycle in 4 days without any interventions of users. Controller is used to activate the ripening cycle and starts the ripening cycle. Ethylene dosage in the room can be preset by the user for 16 to 24hrs. The major requirement of the customer is to produce ripens and to release in batches consistently and uniformly ripened.